Precautions for using drum coal washing machine

TIME:2024-01-05

CLICK:97次

1、 Metal and other foreign objects are strictly prohibited from entering

the cyclone of the coal washing machine to prevent accidental damage to the

cyclone.

2、 Regularly inspect the wear and tear of incoming materials and product

exports, and replace them on time to ensure the sorting effect.

3、 When dealing with blockages and replacing components, the flange can be

opened for repair or replacement. Avoid heavy hammering to avoid damaging the

wear-resistant lining.

4、 During operation, the inlet of raw materials and the outlet of products

should be checked regularly. If blockages or other abnormalities are found, they

should be dealt with in a timely manner.

Troubleshooting and maintenance of drum coal washing machine

1. Carefully check whether all connections are secure and whether all

components are in good condition anytime and anywhere. If any abnormal

situations are found, notify maintenance personnel in a timely manner for

maintenance.

2. Regular inspections should be carried out on parts such as the pull

plate trolley, sprocket chain, bearings, piston rods, etc. to keep all matching

components clean and ensure flexible movement. The synchronization of the pull

plate trolley and the suspension of the chain should be adjusted in a timely

manner.

3. Regular insulation and reliability tests should be conducted on the

electronic control system. If poor accuracy and inflexibility of actions caused

by electrical components are found, they should be repaired or replaced in a

timely manner.

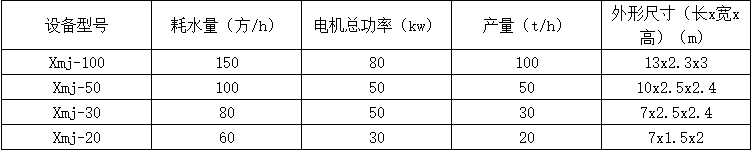

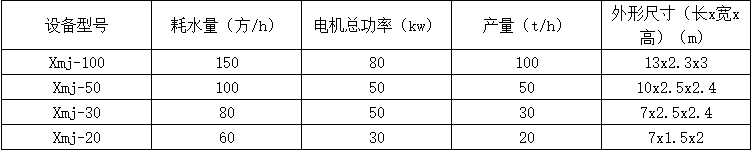

Technical parameters of drum coal washing machine: