Explanation of the workflow of coal washing equipment

TIME:2024-01-05

CLICK:129次

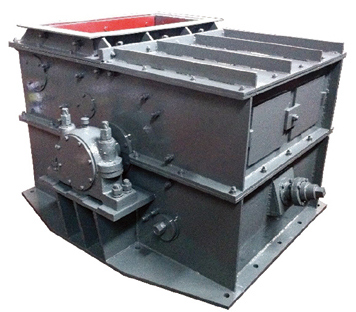

Coal washing equipment is composed of multiple sets of different mechanical

equipment. Generally, the purchaser appears as a complete set. Those who are

knowledgeable will not say where the problem lies with the coal washing

equipment, but rather a specific equipment such as a jig and flotation machine;

The raw coal undergoes preparation, sorting, dehydration, drying, and final

processing to complete the washing process. The working principle of the coal

washing equipment was introduced a few days ago by the editor, and you can

review it again.

Among them, the coal washing equipment needs to first receive the raw coal,

store, crush, and screen it, and use a jigger for flotation. The lump coal, fine

coal, clean coal, and coal slurry in the raw coal need to be dehydrated, and

then dried using thermal energy. After treating the coal slurry water, it can be

used. In response to low-carbon environmental protection policies, it is

filtered and recycled, so there is no need to worry about wasting water.

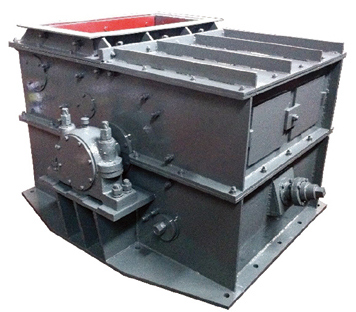

When the coal washing equipment screens out products of two or more levels,

there is a problem with the arrangement order of the sieve surface with a large

and small sieve hole. The material sent into the sieve for screening is called

the incoming raw material, the material that does not pass through the sieve

hole is called the screened material, and the material that passes through the

sieve hole is called the screened material; A screening sequence from small to

large can be adopted, first screening out the fine coal particles in the

material, and then gradually screening out the coal blocks with larger particle

sizes; It is also possible to use a screening sequence from large to small,

first screening out coal blocks with larger particle sizes, and then gradually

screening out coal blocks with smaller particle sizes.

Due to the fact that large blocks of coal in the material are screened out

first, the phenomenon of collision and crushing of large blocks of coal on the

screen surface is reduced. Therefore, the screening sequence from large to small

is widely used in coal washing equipment. The coal amount on the small screen

hole screen surface is reduced, allowing more opportunities for difficult to

screen fine coal to pass through. The screen surfaces of each layer are

overlapped and assembled, and the screen occupies a smaller area of the factory

building.